Brake Line Flares: Metric & SAE, Inverted & Bubble

Published: October 3, 2017

This essay was written based on my experience with Miata brake lines but should be applicable to any car using metric brake line flares, as well as to other flared pipe unions.

How A Flare Works

A flare pipe union seals by pushing two metal pipes together. The ends of the pipes are angled so that there is a male and a female end; the male end pressing against the female end creates the seal.

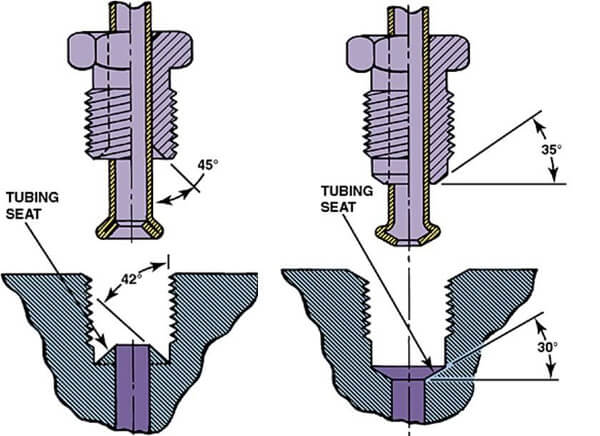

Double inverted flare on the left, bubble flare on the right:

In a typical brake line application, the hard line end of the union is the female end - the brake pipe itself is expanded around the center. The hard line also has the nut that applies force necessary to seal the junction. The soft line end is the male end.

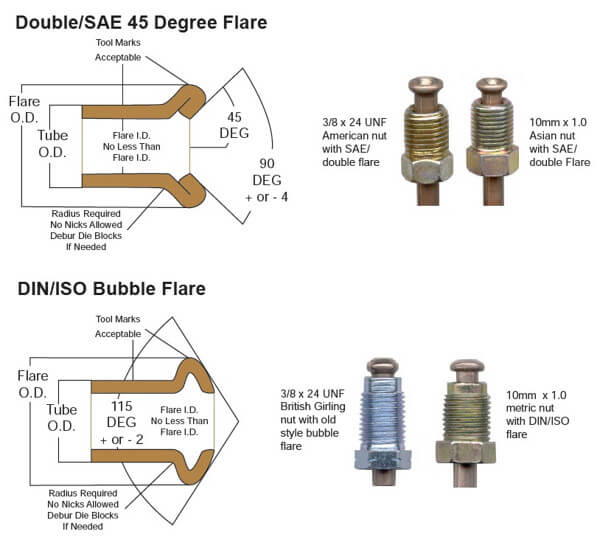

Here is another schematic of the metric/SAE double inverted and DIN/ISO bubble flares with photos of the female ends as found on automotive brake hard lines:

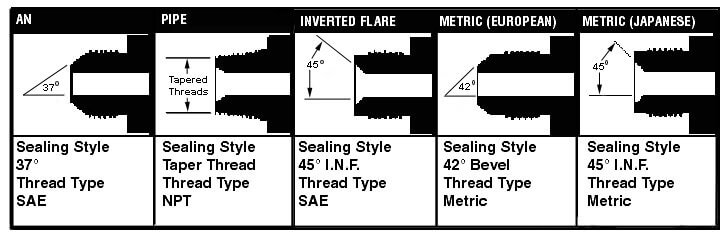

A close-up of the tube ends of various flare types:

This is what the junction looks like assembled:

Note that the angles on male and female ends are not the same. In the first image above, the SAE double inverted flares are considered to have a 45 degree angle - this angle matches the female end of the fitting, whereas the male end has a 42 degree angle. During assembly, as the tube nut is tightened, the male end deforms to match the angle of the female end.

Some other flare types:

Metric Vs SAE Flares

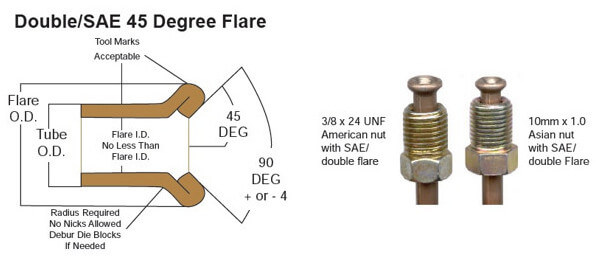

Metric double flare and SAE double flare fittings are constructed from the same principles but with different angles. Referring back to the schematic, SAE double flare uses a 45 degree angle:

JIS metric double flare, as used in Miatas and other Japanese-manufactured vehicles, employ a 37 degree angle.

The far right image on the above illustration shows an SAE double flare with a metric (M10x1.0) tube nut. This is not to be confused with a metric double flare with the same metric tube nut - the angle of the flare itself is critical for the junction sealing.

A proper flare junction uses the same flare type on both male and female ends. Cars like Miatas are configured like this from the factory: they employ M10x1.0 tube nuts and female JIS metric double flares on hard lines and male JIS metric double flares on soft lines.

Issue arise when one mixes SAE and metric fittings and fasteners in a single brake system, because in the US the SAE fittings and fasteners are more commonly available. Due to the differences in flare angles (45 vs 37 degrees), the junction of an SAE inverted flare and a metric inverted flare will not seal properly if tightened to normal specifications. However, if the tube nut is overtightened, eventually one of the ends will form the other end to the same angle, thus creating a seal. In my experience the female end of the hard line alters the male end of the soft line.

Because higher than normal force is required to squish the mismatching flare ends together, assembling a junction in this fashion increases the risk of rounding off the tube nut. Subsequent disassembly also carries increased risk of rounding off the tube nut as it was tightened to a higher than normal torque. Furthermore, as the shape of the tube itself is changed during assembly it is possible to reduce the size of the opening below the diameter of the tube, though I believe this to be rather unlikely given that the angle change is relatively small (8 degrees, from 45 to 37).

On the topic of tube nuts, if one uses SAE flared hard lines with SAE tube nuts the size of the tube nuts - 3/8" or 9.5 mm - is close to the 10 mm size of the metric tube nuts but not quite the same. Attempting to loosen SAE tube nuts with the metric 10 mm flare nut wrench, especially if the SAE nuts were overtightened to compensate for the flare angle difference, is likely to result in rounded off tube nuts during disassembly.

Reuse Of Mutated Brake Lines

Suppose one replaced a brake hard line on a car with an SAE flared hard line, and subsequently wanted to reuse the soft lines on another car with original hard lines. What would happen?

If the hard lines were made of harder material than soft lines, as has been the case in my experience, the soft lines upon original assembly would have been altered to have the SAE 45 degree angle on the flare fitting. Even though these lines originally were the correct Miata part they have become SAE flared soft lines; putting them on a different car with all metric lines and fittings makes the connections leak, possibly heavily, even after overtightening the tube nuts.

A way to repair this situation is to squish the soft lines the second time to their original 37 degree angle. I've found that this is not possible by simply tightening the tube nuts even with a flare wrench - the torque that can be applied to the nuts before they round off is insufficient. However, by using small needle nose locking pliers the tube nut can be turned further and eventually the male seat of the fitting will be conformed to the female end on the hard line.

Naturally turning the tube nut with locking pliers tends to damage the nut, as well as potentially the tube nut threads. This repair is best avoided on connections that need to be successfully disassembled in the future - even stainless steel soft lines are not very expensive and should be the preferred option.

Visit our

Visit our